Electric combination boilers, known for their energy efficiency and compact design, face challenges from corrosion and scale buildup over time. Stainless steel, with at least 10.5% chromium, is a key material due to its superior corrosion resistance and scale prevention. Regular maintenance, including flushing, cleaning with solutions or vinegar, insulation, and chemical treatment, is crucial for optimal performance, energy efficiency, and extended lifespan of these boilers in residential and commercial HVAC applications.

“Unveiling the secret behind robust performance in electric combination boilers, this article delves into the remarkable resistance of stainless-steel models against corrosion and scale buildup. With a focus on maintaining these essential appliances, we explore the science behind their durability.

From understanding the enemies—corrosion and scale formation—to embracing the benefits of stainless steel, you’ll discover practical tips for longevity. Learn how regular maintenance ensures your electric combination boiler remains a reliable, efficient, and long-lasting solution.”

- Understanding Corrosion and Scale Formation in Electric Combination Boilers

- The Role of Stainless Steel in Preventing Corrosion and Scale Buildup

- Maintenance Tips for Longevity: Keeping Your Electric Combination Boiler Scaleproof

Understanding Corrosion and Scale Formation in Electric Combination Boilers

Electric combination boilers, also known as combi boilers or instant hot water heaters, are a popular choice for residential and commercial space heating systems due to their energy efficiency and compact design. However, like all water-based heating systems, they face challenges from corrosion and scale buildup over time. Understanding these processes is crucial in ensuring the longevity and optimal performance of electric combi boilers.

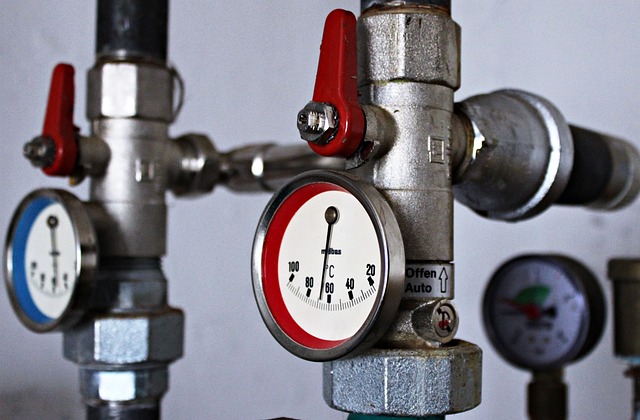

Corrosion occurs when metal components of the boiler, such as the heat exchanger, are attacked by moisture in the water supply. This can lead to the formation of rust, which not only reduces the boiler’s efficiency but also poses a risk of failure. Scale, on the other hand, is mineral deposits that accumulate inside the boiler, usually from hard water containing high levels of calcium and magnesium. These deposits can insulate the heating elements, reducing their effectiveness, and ultimately clogging the system if left unchecked. Regular maintenance, including flushing and using water treatment chemicals, is essential to mitigate these issues in electric central heating systems like tankless electric boilers and compact boiler systems.

The Role of Stainless Steel in Preventing Corrosion and Scale Buildup

Stainless steel plays a pivotal role in the design of modern electric combination boilers, offering superior resistance to both corrosion and scale buildup. This is particularly advantageous for electric combi boilers and other compact boiler systems, which are increasingly popular due to their energy efficiency and space-saving designs. The metal’s innate properties make it an ideal material for these advanced heating systems.

Stainless steel, as the name suggests, contains a minimum of 10.5% chromium, which forms a protective layer known as passivation when exposed to oxygen. This layer prevents corrosion, even in harsh environments. Additionally, its low carbon content reduces the risk of crevice corrosion, commonly observed in traditional metal structures. As a result, electric combi boilers made from stainless steel can maintain their performance and efficiency over extended periods, ensuring optimal space heating and hot water supply without the need for frequent maintenance or costly replacements, making them a preferred choice for both residential electric heating and commercial applications, including electric HVAC boilers.

Maintenance Tips for Longevity: Keeping Your Electric Combination Boiler Scaleproof

Proper maintenance is key to ensuring your stainless-steel electric combination boilers resist corrosion and scale buildup over time. Regular cleaning and flushing are essential practices for prolonging the life of these efficient heating systems. Start by draining the boiler periodically, especially in areas with hard water, as it’s a primary cause of scale accumulation. Use specialized cleaning solutions or white vinegar to remove any mineral deposits or residue.

Additionally, insulating your electric combi boilers can prevent temperature fluctuations and reduce the risk of corrosion. Protecting these compact boiler systems from extreme conditions ensures optimal performance and energy efficiency. Incorporating regular maintenance into your routine will not only maintain the integrity of your combination heating systems but also ensure consistent and reliable residential electric heating or space heating system functionality, making them a sustainable choice for electric central heating or electric hot water heating needs.

Electric combination boilers, renowned for their efficiency, now offer enhanced longevity thanks to stainless steel’s corrosion and scale resistance. By understanding the factors that lead to corrosion and scale formation, we can appreciate the strategic use of this material in their construction. Regular maintenance, including periodic cleaning and checking for leaks, ensures these boilers remain not just effective but also durable. Investing in a stainless-steel electric combination boiler is a wise choice, guaranteeing years of reliable performance without the need for frequent replacement or costly repairs.